LEICHTMETALL

ALUMINIUM GIESSEREI

HANNOVER

High-quality aluminum alloys from LEICHTMETALL Aluminium Giesserei Hannover GmbH

MAKING ALUMINIUM STRONGER

Not all aluminum is created equal. At LEICHTMETALL Hannover, our aluminum foundry combines the highest precision and quality with extensive experience and flexibility. In every bar.

Continuous casting was invented at the Hannover plant as early as the 1920s and is still the most significant production method for aluminum billets today. We are continuously developing continuous casting with our own hot-top molds. LEICHTMETALL Hannover produces aluminum of the highest quality and grade. At LEICHTMETALL, we have been continuously optimizing our processes for the use of recycled aluminum for over 30 years and can offer application-specific alloys in our foundry that are setting new standards.

Aluminum production at the Hanover site in Germany – “Made in Germany” quality

With two 50-ton channel induction furnaces and a 10-ton mobile crucible furnace, our aluminum foundry produces more than 35,000 tons of aluminum annually in Germany. Our team of international minds stands for fairness and sustainability when it comes to cooperation based on shared values based on transparency and reliability.

Quality check after each step

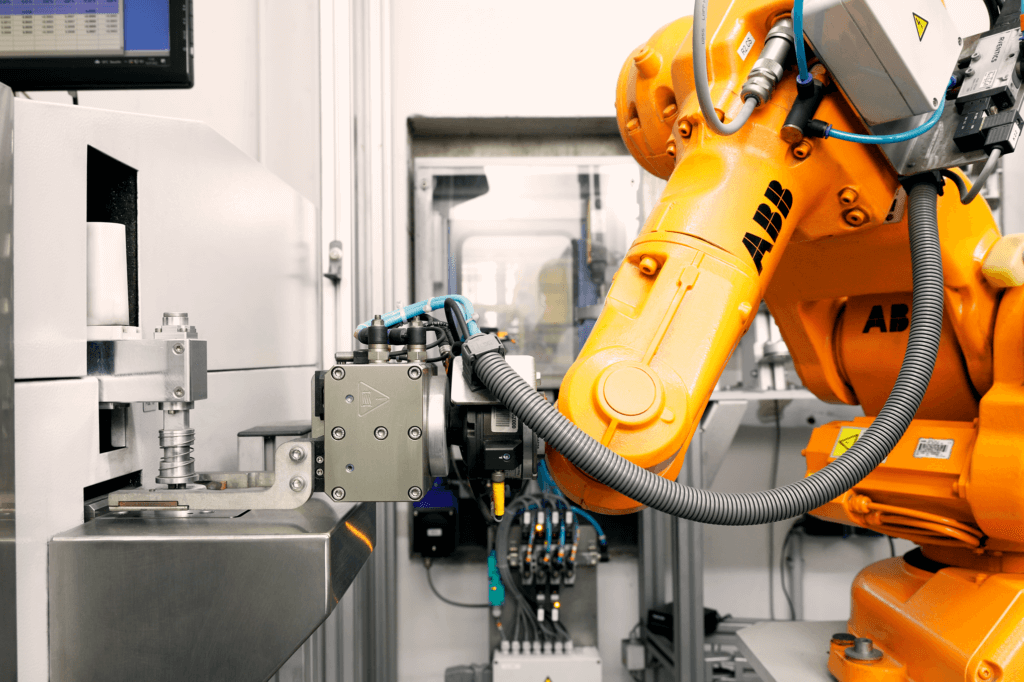

To produce high-strength aluminum in premium quality, our facilities are equipped with the latest technology and a diverse range of machinery complete with our own in-house laboratory. State-of-the-art measuring equipment, a state-of-the-art laboratory process data management system (LPDM) and fully automated ultrasonic testing equipment from renowned manufacturers ensure every one of our customers‘ requirements is met and enable our foundry to maintain consistently high quality levels for every ingot.

Two 50-ton channel induction furnaces

State-of-the-art quality assurance equipment

Bars in various diameters

Definition of continuous casting

Continuous casting is the process of casting billets as a single piece in the form of a strand.

Continuous casting is when the aluminum is poured through a bottomless mold and then withdrawn with a solidified shell and usually still liquid core in a downward, sideways or upward direction. After solidification, the strand is pulled out of the casting platform.

In our Hanover foundry, castings are cast as round billets up to a length of 7,000 mm using the level vertical continuous casting process. The dimensional range of the molds extends from a diameter of 162 mm up to 700 mm, also depending on the alloy and number of strands.

From 2023, we will be able to cast diameters of up to 1,150 mm.

Overview of our main alloys

High-strength alloy applications

We offer an extensive range of high-strength alloys. Not only do we produce our top alloys such as EN AW-2017 / A or EN AW-7075, we also produce alloys to meet your needs and requirements. You can expect high flexibility and quality in each precisely cast aluminum round billet thanks to our manufacturing expertise. All using our customized in-house, hot-top gravity die casting.

Our certifications